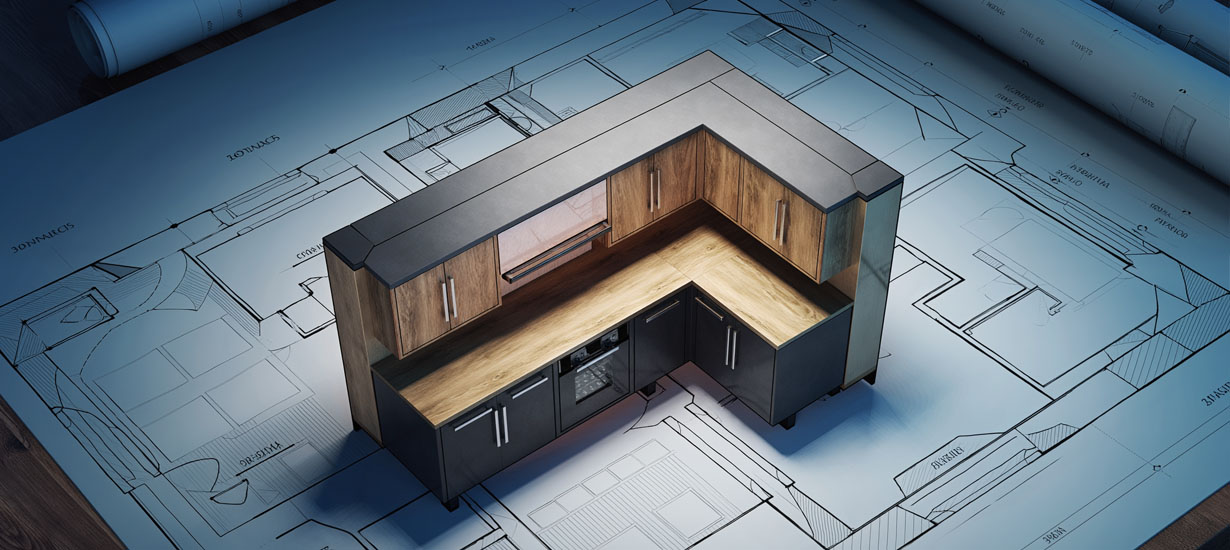

Overcoming Challenges in Complex Millwork Projects Through Precise Drafting

Complex millwork projects rarely fail because of craftsmanship—they fail because of unclear documentation. Tight tolerances, layered assemblies, and coordination with multiple trades make millwork drafting services one of the most critical components of project success.

At Breakline Drafting Solutions, we help millwork shops and project teams navigate complexity by producing shop drawings that clarify intent, reduce risk, and support fabrication and installation.

1) Managing Complex Assemblies and Intersections

High-end millwork often involves layered construction: face frames, panels, reveals, backing materials, lighting integrations, and trim—all intersecting in tight spaces.

Clear drafting breaks these assemblies down into understandable components using detailed elevations, sections, and callouts so fabricators and installers know exactly how everything comes together.

2) Coordinating with Multiple Trades

Millwork rarely exists in isolation. Electrical, plumbing, HVAC, fire protection, and architectural finishes frequently pass through or terminate within millwork assemblies.

- Cabinetry integrating power and lighting

- Wall panels coordinating with diffusers or sprinklers

- Millwork aligning with ceilings, flooring, and glazing

Professional millwork drafting services anticipate these interfaces early, reducing conflicts before they reach the field.

3) Addressing Tight Tolerances and Field Conditions

Complex projects often allow little margin for error. Slight variations in walls, floors, or framing can affect the fit and finish of custom millwork.

Accurate drafting accounts for these realities by defining tolerances, scribe conditions, and installation sequencing—helping installers adapt without compromising design intent.

4) Controlling Revisions and Scope Changes

Complex projects tend to evolve. Design changes, coordination updates, and client revisions can quickly create confusion if documentation isn’t tightly controlled.

Clear revision tracking, consistent sheet organization, and disciplined drafting workflows ensure everyone is working from the latest information—reducing costly mistakes.

5) Reducing Risk on High-Value Projects

The more complex the millwork, the higher the risk. Errors can lead to fabrication delays, expensive remakes, and schedule impacts that ripple across the entire project.

Detailed millwork shop drawings reduce that risk by clearly defining scope, materials, assemblies, and installation intent before fabrication begins.

Why Clear Drafting Matters on Complex Millwork Jobs

Complex millwork projects succeed when drawings do more than describe appearance—they guide fabrication and installation with precision.

- Fewer RFIs and clarification requests

- Cleaner fabrication planning

- Smoother installations with fewer field modifications

- Reduced overall project risk

Work With a Millwork Drafting Partner That Understands Complexity

If your projects involve detailed assemblies, tight tolerances, or high coordination demands, Breakline Drafting Solutions provides millwork drafting services designed to support complex work from start to finish.

Learn more about our Architectural Millwork Shop Drawings

Explore our full drafting services

Request a quote today